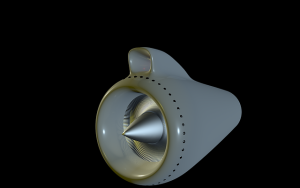

Turbofans are commonly used in commercial airliners. Also known as fanjets, they are jet engines that burn fuel and air. Like the internal combustion engines in cars and trucks, turbofans have a combustion chamber. They such air and fuel into this combustion chamber. As this mixture of fuel and air is burned, it will produce hot exhaust gases that propel the airplane forward. Here are five facts about turbofans and how they work.

#1) More Efficient Than Turbojets

Turbofans are more efficient than turbojets. Both turbofans and turbojets are designed to burn fuel and air. Turbofans, however, have a larger fan at the front. This super-sized fan maximizes thrust while subsequently improving fuel efficiency. Commercial airlines often use turbofans because of their fuel-efficient properties, as it allows them to save money on fuel expenses.

#2) Bypass Ratios

Not all of the air pulled from the airplane’s exterior will enter the turbofan’s combustion chamber; some of it will be diverted elsewhere, such as the cabin. Bypass ratios represent how much air “bypasses” the combustion chamber. Some turbofans have a bypass ratio of 4:1, whereas others have a bypass ratio of 9:1. A bypass ratio of 4:1 means that for every one unit of air that enters the combustion chamber, four units of air will be diverted elsewhere.

#3) Noise Reduction

In addition to being fuel efficient, turbofans are known for producing minimal noise. They don’t run completely silently. Nonetheless, turbofans produce less noise than other types of jet engines. This is due in part to their ability to divert air. The bypass air works like the muffler on a car or truck. As air is diverted away from the combustion chamber, it suppresses noise. Many turbofans are also designed with acoustic liners and other sound-dampening features to further reduce their noise.

#4) Thrust-to-Weight Ratio

Another ratio used with trubofans is thrust-to-weight ratio. It’s used to measure the performance of a turbofan. Thrust-to-weight ratio specifically represents the amount of thrust produced by a turbofan relative to how much it weighs. A higher thrust-to-weight ratio results in greater performance. Therefore, turbofan manufacturers often optimize their engines for a high thrust-to-weight ratio.

#5) Monitoring Systems

Most turbofans are equipped with monitoring systems. Monitoring systems, as the name suggests, are designed to evaluate and monitor the performance of turbofans. Some of the most common monitoring systems used for turbofans include Engine Condition Monitoring (ECM) systems and Engine Health Monitoring (EHM) systems.