Washers are commonly used to distribute the load of threaded fasteners. When you drive a threaded washer through two or more parts, the load will be focused directly below the head. This concentrated tension can damage parts, which is where washers come into play: They provide additional surface area for the fastener’s load, thereby protecting parts from damage. There are different types of washers, however, including tooth.

Overview of Tooth Washers

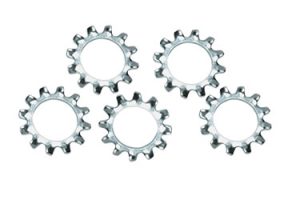

Tooth washers are ring-shaped fasteners with serrations. Also known as star washers, they are designed to prevent threaded fasteners from loosening due to vibrations.

When machines or equipment vibrate, it can cause nuts and bolts to loosen. Threaded fasteners such as these may gradually loosen. As they loosen, the threaded fasteners will fail to securely hold the parts together. Tooth washers prevent this from happening by gripping the exposed surface of the parts.

How Tooth Washers Work

Tooth washers work by digging into parts. Like all washers, they distribute the load of threaded fasteners. You can drive a bolt through the center opening of a washer so that the head of the bolt will press against the sides of the washer. Tooth washers, though, also resist vibration-related loosening by digging into parts with their serrations.

When you tighten a bolt alongside a tooth washer, the serrations will dig into the exposed surface of the part as well as the underside of the bolt’s head. This biting effect adds friction that protects the bolt from loosening due to vibrations.

Tooth washers are commonly used in electrical applications. They ensure conductivity by cutting through oxidation on metal parts. Metal parts can experience corrosion. If left unchecked, corrosion can disrupt their ability to provide a safe pathway for an electrical current. Tooth washers ensure electrical conductivity by cutting through corrosion and rust, making them ideal for grounding and bonding applications.

The Different Types of Tooth Washers

There are different types of tooth washers, including external tooth and internal tooth. They both feature serrations, and they both protect against vibration-related loosening. External tooth washers feature serrations along the outside, whereas internal tooth washers feature serrations along the inside.

Internal tooth washers work best for small fasteners. The serrations extend inward, meaning they cover a smaller surface area. For large fasteners, you may want to use an external tooth washer. The outward-facing serrations will cover a larger surface area.