Washers are commonly used to protect parts from stress-induced damage. These flat, disc-shaped fasteners are designed to distribute the load of a bolt or screw. Rather than driving a bolt or screw directly through an object, you can drive it through a washer, followed by the respective object. The washer will distribute the fastener’s load across a wider area of the object so that stress-induced damage is less likely to occur.

While nearly all washers can distribute the load of a fastener, some of them offer other benefits. There are sealing washers, for instance. Sealing washers can keep debris out of sensitive parts and spaces. For a better understanding of sealing washers and how they differ from traditional washers, keep reading.

What Are Sealing Washers?

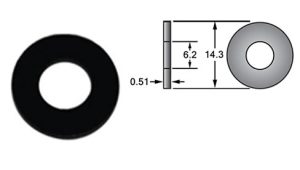

Sealing washers are flat, disc-shaped fasteners that are designed to create a tight seal between two mating surfaces. Also known as sealing rings, they prevent the intrusion of unwanted elements, such as dirt, dust and moisture.

Sealing Washers vs Traditional Washers: What’s the Difference?

Both sealing washers and traditional washers feature a similar shape: They are flat, disc-shaped fasteners with a hole in the center. While they look similar, however, sealing washers and traditional washers differ in several ways.

Sealing washers can still protect the parts with which they are used from stress-induced damage — just like traditional washers. The difference is that sealing washers provide sealing as well.

Traditional washers are typically made of metal, such as stainless steel, carbon steel or aluminum. Sealing washers, on the other hand, are typically made of an elastomer.

Common materials in which sealing washers are made include the following:

- Rubber

- Silicone

- Neoprene

- Nylon

Sealing washers are also more versatile than traditional washers. Traditional washers are used exclusively with a threaded fastener, such as a bolt or screw. While sealing washers are often used with a threaded fastener as well, they can be used with other objects as well, including pipes and fittings.

How Sealing Washers Work

The sealing power of these specialized washers can be attributed to the elastomeric material from which they are made. They are naturally elastic, meaning they can be compressed without sustaining any permanent damage. When pressure is removed from a sealing washer, it will return to its original shape.

As a sealing washer compresses under the load of a fastener or object, it will create a tight seal. The sealing washer will fill the small but open mating space, thereby preventing the intrusion of unwanted elements.