Have you heard of low-pressure hoses? They are commonly used in airplanes. From wide-body airplanes to small commuter airplanes, many airplanes feature one or more low-pressure hoses. Whether you’re building your own airplane — or if you’re simply an aviation enthusiast — you might be wondering how low-pressure hoses work.

What Are Low-Pressure Hoses?

Low-pressure hoses are durable, semi-flexible hoses that are designed for low-pressure applications. You can find them in different materials. With that said, most low-pressure hoses are made of synthetic rubber.

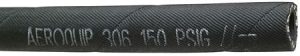

Aeroquip low-pressure hoses are a popular choice for airplanes. They are made of high-grade synthetic rubber that’s reinforced with cotton braid. The end result is a strong yet semi-flexible hose that can “flex” when used in low-pressure applications.

Some of the benefits of low-pressure hoses include the following:

- Durable and long-lasting

- Resistant to deformation

- Lightweight

- Resistant to rusting and corrosion

Air and Vacuum Lines

Most low-pressure hoses are used for air and vacuum lines in airplanes. Air lines feed air to various systems, whereas vacuum lines create a “suction” for various systems. For air and vacuum lines, many airplanes use low-pressure hoses.

De-icing systems are often powered by low-pressure hoses. In cold climates, airplanes may deliver compressed air over the wings and fuselage to remove ice. Landing gear may also be powered by low-pressure hoses. Low-pressure hoses can feed air to an airplane’s pneumatic landing gear. Regardless, low-pressure hoses are typically used as air and vacuum lines in airplanes.

Fittings

Low-pressure hoses support fittings. Also known as a coupler, a fitting is a connector component that’s designed to join two or more hoses. You can slide a fitting over the end of one low-pressure hose, after which you can connect it to another low-pressure hose.

Fittings simplify the process of installing low-pressure hoses. As long as you choose the right type of fitting — and the right size — you can slide it over the end of a low-pressure hose. You can then connect it to another low-pressure hose for quick and easy installation.

Clamps

In addition to fittings, low-pressure hoses support the use of clamps. Clamps are simple devices that are designed to clamp down on the end of a hose so that fluid or air doesn’t leak out of it.

Low-pressure hoses can leak without a clamp. As pressurized air flows through them, some of this air may escape out of mating surfaces. Clamps prevent this from happening by sealing these areas. After sliding a low-pressure hose over a nozzle or similar mating surface, you can install a clamp. The clamp will apply consistent pressure to the hose so that it doesn’t leak.