When installing fasteners on an airplane, you may want to use locking wire. Airplanes feature thousands of fasteners. Over time, some of these fasteners may loosen. Locking wire can “lock” them in place, however, so that they don’t loosen.

What Is Locking Wire?

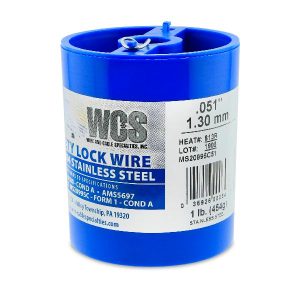

Also known as safety wire, locking wire is a type of thin, heavy-duty wire that’s used in conjunction with fasteners. You can use it with screws, bolts and nuts. Locking wire is designed to secure fasteners in place.

How Locking Wire Works

Even if you’ve come across locking wire when shopping for aerospace fasteners, you might be unfamiliar with its mechanics. There are different types of locking wire. You can find locking wire made of different materials, such as stainless steel and aluminum. And you can find it in different sizes. Regardless, all types of locking wire work in the same way.

When installing fasteners, you can run locking wire under the heads. The locking wire should be tight under the fasteners’ heads. You essentially want to twist the locking wire under the head of each fastener, thus creating a daisy-chain-like formation. The locking wire will reinforce the fasteners with which it’s used so that they are better protected against loosening.

Why Airplanes Use Locking Wire

Airplanes produce vibrations. Vibrations are the result of turbulence. During flight, turbulence will cause airplanes to vibrate — and these vibrations can affect the airplane’s fasteners.

Fasteners can loosen when exposed to vibrations over an extended period. It may not happen after immediately. But after dozens or hundreds of flights, some of the fasteners used in an airplane’s construction may loosen. Loose fasteners, of course, are a safety hazard. Fortunately, locking wire can secure fasteners in place so that they are better protected against loosening.

Not all fasteners require the use of locking wire. Rather, locking wire is typically designed for traditional, temporary fasteners. There are temporary fasteners, and there are permanent fasteners. Permanent fasteners, such as rivets, don’t require locking wire. After being installed, permanent fasteners will remain in place.

Temporary fasteners, conversely, can benefit from locking wire. Temporary fasteners are removable. The removable nature of temporary fasteners makes them susceptible to loosening when exposed to vibrations.

In Conclusion

Certain fasteners are susceptible to loosening due to vibrations. Locking wire, however, can secure them in place. Locking wire consists of thin metal wire that’s designed for use under the head of fasteners. It will secure the fasteners in place so that they don’t become loose.