A typical medium-sized airplane has over 100 miles of cables and wires. Larger airplanes, of course, have even more wires and cables. Rather than allowing them to clutter spaces in tunnels and behind access panels, engineers typically use a management solution, such as lacing cord.

What Is Lacing Cord?

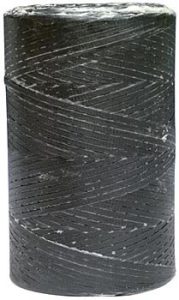

Lacing cord is a cable and wire management solution consisting of heavy-duty cord. It’s used to neatly hold cables and wires in place.

While there are different types of lacing cord, they are all made of durable materials. You can find lacing cord made of nylon, polyester and even fiberglass. Depending on where and how it’s used, it may be coated in PTFE for additional durability. PTFE helps the cord resist heat and chemicals.

Benefits of lacing cord include the following:

- Protects wires and cables from damage

- Improves airflow in spaces containing wires and cables

- Makes maintenance easier

- Strong, durable and resistant to heat and chemicals

- Flexible and easy to work with

How Technicians Use Lacing Cord

Technicians use lacing cord by wrapping it around nearby cables or wires. The most common methods include continuous lacing and spot tying. Continuous lacing involves wrapping the lacing cord around a nearby wire or cable in a spiral pattern from one end to the other end. Spot typing, on the other hand, involves the creation of knots at specific intervals near the connectors.

Lacing Cord vs Cable Ties

Cable ties can also be used to manage cables and wires. In the aviation industry, though, lacing cord is often preferred. Cables tie have sharp ends. After wrapping a cable tie around a cable or wire, the sharp end it will stick out, which may cut into the insulation. Lacing cord doesn’t have sharp ends, so there’s little or no risk of it cutting into insulation.

Lacing cord also weighs less than cable ties. Its lightweight properties make it ideal for aviation-related cable and wire management.

Lacing cord still requires maintenance, however. During inspections, maintenance crews will typically check lacing cord for signs of fraying or loosening. Since it’s exposed to vibrations and temperature changes — like nearly all aircraft parts — damage may occur from regular use. Proper upkeep helps to prevent electrical issues associated with worn lacing cord.

In Conclusion

Lacing cord plays a crucial role in keeping an aircraft’s electrical systems safe, organized and efficient. By holding wires firmly in place, it prevents damage, reduces clutter, and helps technicians perform maintenance more easily. Its strength, heat resistance, and lightweight properties make it the preferred choice over cable ties in most aviation settings.