Have you heard of locking wire? It’s used extensively in the aerospace and manufacturing industries to secure fasteners in place. Not all fasteners require locking wire. If a fastener is exposed to constant and/or forceful vibrations, however, this otherwise simple component could prove invaluable. Unless you’re familiar with it, though, you might be wondering how exactly locking wire is able to secure fasteners in place.

Have you heard of locking wire? It’s used extensively in the aerospace and manufacturing industries to secure fasteners in place. Not all fasteners require locking wire. If a fastener is exposed to constant and/or forceful vibrations, however, this otherwise simple component could prove invaluable. Unless you’re familiar with it, though, you might be wondering how exactly locking wire is able to secure fasteners in place.

What Is Locking Wire?

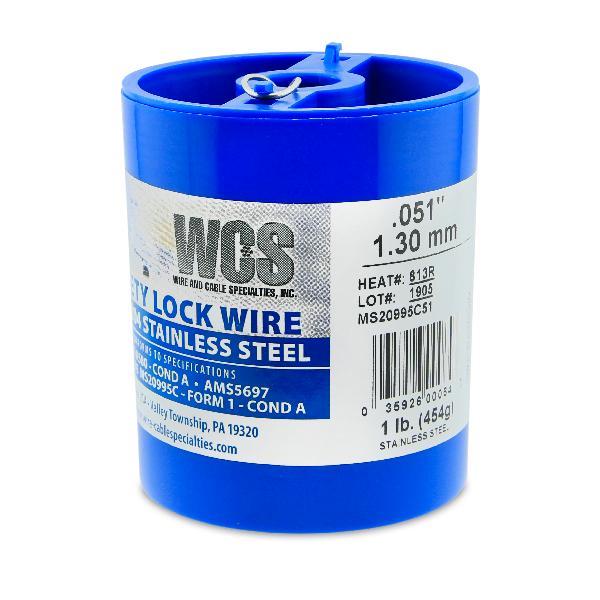

Also known as safety wire, locking wire consists of metal wire — usually about 0.5 to 1 millimeters in diameter — that’s wrapped around one or more fasteners. Whether it’s a screw, bolt or any other type of fastener, it’s not uncommon for vibrations to loosen and dislodge fasteners from the respective object in which they are installed. An airplane, for example, will produce heavy vibrations during operation that may cause bolts to loosen over time. Locking wire, however, prevents this from happening by holding the respective fastener or fasteners in place.

The Basic Function of Locking Wire

When a company is manufacturing a product, it may use locking wire in conjunction with one or more fasteners. Although it sounds like a complex tool, locking wire is actually pretty simple and straightforward. First and foremost, the fasteners are inserted into the appropriate object. After installing the fasteners, a worker then wraps the locking wire around the head of the fasteners. If two fasteners are used, for example, locking wire may be wrapped around both heads of the fasteners.

The Different Types of Locking Wire

All locking wire is designed to secure fasteners in place, but there are several different types of locking wire, each of which is unique. The most common type of locking wire is medium-gauge stainless steel wire. It consists entirely of stainless steel strands, which are woven together to provide a superior level of strength.

The size of the locking wire also varies. As previously mentioned, most locking wire measures about 0.5 to 1 millimeters in diameter. Some, however, can measure over 1.5 millimeters in diameter. Thicker locking wire offers a higher level of protection against vibrations. If the locking wire is too thick, on the other hand, it may not fit over the heads of the fasteners with which it’s used.

Neither locking wire nor any other locking solution is a foolproof means of securing a fastener. With that said, it can certainly help to prevent fasteners from loosening due to vibrations. Locking wire is wrapped around the heads of fasteners, thereby holding them in place.