Whether it’s a small single-engine husky or a massive Airbus A300-600ST , aircraft are designed in a three-stage process. This consists of the conceptual design phase, the preliminary design phase, and finally the detail design phase. To learn more about this process and how it works, keep reading.

Whether it’s a small single-engine husky or a massive Airbus A300-600ST , aircraft are designed in a three-stage process. This consists of the conceptual design phase, the preliminary design phase, and finally the detail design phase. To learn more about this process and how it works, keep reading.

Conceptual Design

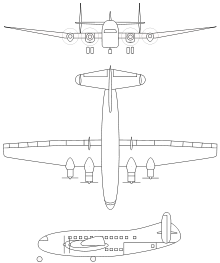

The first stage of aircraft design is conceptual design. This is the very beginning of the design process in which rough sketches are created with respect to the aircraft’s configurations. Designers seek to achieve a design that meets all of the aircraft’s requirements, including aerodynamics, propulsion, performance, structural systems, control systems and more. Designers must also consider elements such as the shape of the aircraft’s fuselage, wing location, enginesize and more.

Preliminary Design

After completing the conceptual design, the next phase is preliminary design. During this stage, the conceptual design is optimized to fit into the necessary parameters. Engineers may use the existing designs to conduct wind tunnel testing and fluid dynamic calculations. Furthermore, structural and control analyses are performed during this stage. Engineers will also look for structural defects and flaws, correcting them before proceeding to the third and final stage of the design process.

Detail Design

Last but not least is the detail design phase. During this phase, engineers must use the existing designs to fabricate the actual aircraft. It specifically determines the design, location and quantity of elements such as rubs, spars, sections and more. Furthermore, all aerodynamic, structural, control and performance aspects are achieved and tested in full in the previous preliminary design stage. The detail design stage, rather, is used to turn these designs into a working aircraft. It may also include flight simulations to test the design and ensure it functions as intended.

The aerospace manufacturing industry continues to grow with each passing year. In 2015, statistics show that aerospace companies contributed more than $144 billion to the nation’s economy in export sales. The industry even has a positive trade balance in excess of $82 billion, making it the largest trade surplus of any manufacturing industry. But in order for the industry to function as intended, companies must design new aircraft, typically using the three-stage process described here.

Hopefully, this will give you a better understanding of aircraft design and its 3-stage process.