When most people think of tape, they envision traditional cellophane tape. Consisting of transparent cellophane with adhesive on one side, cellophane tape is commonly used in classrooms and offices. In the aviation industry, other types of tape are typically used, such as aluminum, speed, high-bonding, erosion and electrical tape.

#1) Aluminum Tape

Aluminum tape is characterized by an aluminum backing. It’s classified as a pressure-sensitive tape, meaning it offers excellent adhesion with light pressure. Aluminum tape doesn’t require heat or substances for activation. Even when pressed gently against a surface, it will remain in place. Its aluminum backing makes it particularly effective at withstanding heat, which is why aluminum tape is commonly used around aircraft engine components and climate control systems.

#2) Speed Tape

Speed tape is one of the most widely recognized types of tape used in the aviation industry. It’s used to make fast, temporary repairs to non-critical components. Fairings, for instance, are often secured using speed tape. Fairings aren’t critically important. Rather, they typically create a more aerodynamic shape while simultaneously reducing drag. If a fairing is loose, pilots or maintenance workers may apply speed tape to secure the fairing until a more permanent repair can be made.

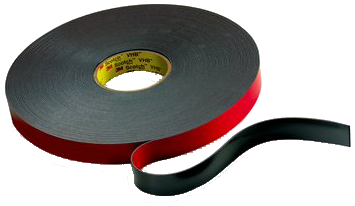

#3) High-Bonding Tape

High-bonding tape is a type of double-sided acrylic tape that’s designed to create a strong and durable bond. It distributes mechanical stress evenly across the surface with which it’s used. The end result is a higher level of protection from unnecessary wear and tear. At the same time, high-bonding tape can reduce noise to promote a quieter flying experience for passengers.

#4) Erosion Tape

Another common type of tape used in the aviation industry is erosion tape. Erosion tape receives its namesake from its ability to protect objects from erosion. It’s commonly used on aircraft wings, control surfaces and fuselages. Erosion can damage these parts and reduce the aircraft’s aerodynamic properties. Erosion tape, however, acts as a protective barrier to shield the underlying surface from direct water exposure.

#5) Electrical Tape

Electrical tape is used extensively in the aviation industry. It’s characterized by a nonconductive design. Most electrical tape is made of polyvinyl chloride (PVC) plastic with a strong adhesive on one side. Unlike aluminum tape and speed tape, PVC-based electrical tape doesn’t conduct electricity. As a result, it’s commonly used to secure wires in aircraft electrical systems.