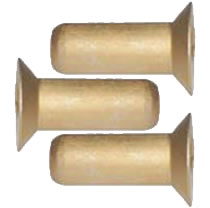

Solid rivets are used extensively in the aerospace manufacturing industry. They are fasteners that, as the name suggests, feature a solid body. Other rivets feature a hollow body, whereas solid rivets feature a solid body. The structural parts of an airplane’s body are often secured using hundreds of solid rivets. Below are five facts about solid rivets you need to know.

#1) Designed for Permanent Use

Solid rivets are designed for permanent use. There are permanent fasteners, and there are temporary fasteners. Temporary fasteners include threaded fasteners like bolts and screws. Permanent fasteners, on the other hand, include rivets. Solid rivets fall under the category of temporary fasteners because they can’t be easily removed after installation.

#2) Available in Different Materials

While most solid rivets are metal, some of them are made of a different type of metal than others. You can find solid rivets made of aluminum alloy, such as aircraft-grade aluminum. You can also find solid rivets made of titanium, and you can find them made of nickel alloy. Each material offers its own advantages. Whether you choose aluminum alloy, titanium or nickel alloy solid rivets, though, you can rest assured knowing that they are strong and durable.

#3) Resistant to Vibrations

One of the reasons solid rivets are used in airplanes is because they are resistant to vibrations. Airplanes will vibrate during flight. Over time, these vibrations can cause temporary fasteners to loosen. Solid rivets are permanent fasteners, however, so they are naturally resistant to vibrations. They will continue to secure the parts with which they are used — even when the airplane flies through pockets of heavy turbulence.

#4) Not the Same as Blind Rivets

Solid rivets aren’t the same as blind rivets. Rivets are considered blind if they only require access to one side of the parts with which they are used. You can install blind rivets by only accessing the front of the parts, for example. Solid rivets require access to both sides of the parts. Most blind rivets are also hollow, whereas solid rivets feature a solid body.

#5) Installed via a Compression Tool

You’ll typically need a compression tool to install solid rivets. A compression tool is a handheld tool that’s designed to deform and the head of a rivet. Solid rivets have a cylindrical body (the shank), and they have a round head. After running a solid rivet through the parts, you can use a compression tool to collapse the head.